Siddha baba bitumen

BITUMEN EMULSION COLD MIX

Cold Mix Emulsion is a mix design nased tailor made bitumen binder. The main feature of this mix design process istoidentify and optimize the binder as per the aggregates available from any source inindia i.e dusty aggregates, soil coated aggregates, clean aggregates, damp aggregates, pea gravel aggregates or (lime mix) aggregates.This binder exceeds IS 8887: 2018 specification of MS and SS-2, technology and can be utilized for following applications as per recently released IRC SP: 100: 2014 Guidelines.

ADVANTAGE

No heating required Cost effcient Easy and unform mixing Low temperature curing Minimum preparation time for surface repair Medium setting time High adhesive properties Stable patch Resistant to stripping by water Environment friendly Bond well with cool, damp surfaces NRRDA recommends that is case of any extra cost of convertibg existing works from Hot Mix to Cold mix technology, the same shall be allowed to be adjusted with “savingd”. NRRDA endeavor to scale up to Green and enviornment friendly road technology needs to be harnssed by all states in the country. It suggests Zero extra cost to the state Exchequer Harnessed By all.

APPLICATION

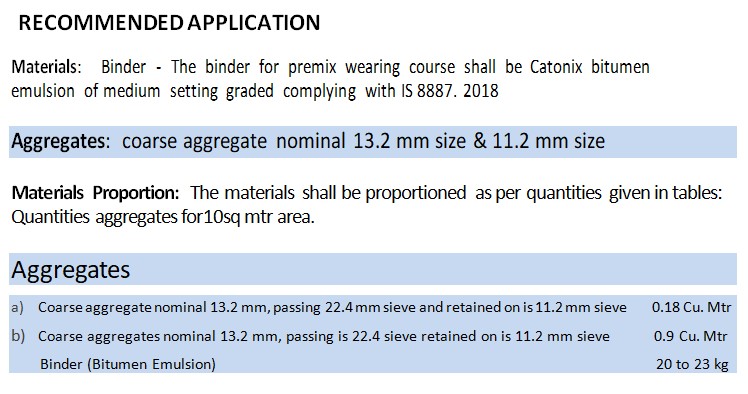

This work shall consist of the preparation, laying and compaction of an open graded premix surfacing of 20 m thikness composed of small sized aggregate premixed with a cationic bitumen emulsion on a previously surface, i accordance with the requirements of these specifications toserve as a wearing course

WATER AND SEASONAL LIMITATIONS

The minimum air temperature for laying shall be 10°C

Preparation of surface : The Surface should be throughly kept clean by mechanical/hand broom, and the dus removed by compressed air.

Preparation Binder: Before opening, the cationic bitumen emulsion drums shall be rolled at a slow speed, to an fro at least 5 times, for adistance of about 10 meters, to distribute any storage sedimentation.

Tack Coat: Take Coat shall be applied over the surface preparatory to laying of the surfacing.

Preparation of Premix : Premixing of cationic bitumen emulsion and aggregates can be carried out in a suitabl mixture such as cold mixing plant as per IS: 5435 (MoRTH revised) or concrete mixture or by pay loader exceptional cases.

When using concrete mixer for preparing the premix, 0.135 cu mtr (0.09 cumtr of 13.2 mm size and 0.045 cu mtr 11.2 mm size) of aggregates per batch shall be used. This quantity will be for 5 sq mtr of road surface with 20 m average thickness. The coarse aggregate of 13.2 mm size shall be places into the mixer followed by 5 to 6.5 kg cationic bitumen emulsion and then the 11.2 mm size aggregates shall be added, followed by 5 to 6.5 kg of cationi bitumen emulsion. After the materials have been thoroughly, the mix shall be immediately transported tothe layin

site insuitable vehicles. Too much mixin shall beavoided

HEALTH AND SAFETY

1. Personal Protection & first aid

a. Respiratory protection not normally required.

b. Hand protection – heat resistant Gloves close fitting at wrest.

c. Eye protection – mono goggles of full face shield.

d. Skin – wash contaminated area immediately with soap and water

e. Eye- rinse immediately with plenty of water for at least 10 minutes and seek medical advice

2. Fire Fighting

a. Specific hazards-product is water based liquid will not readily bum

b. Extinguishing media – foam, carbon-di-oxide, dry chemical e extinguisher.

3. Transport storage, handling & disposal :

a. Transport : -can be transported normally both in bulk and packed.

b. Handling:-when handling product in drums, safety footwear should be worn and proper handling equipment should be used.

c. Wastage arising from spillage or tank cleaning should be disposed of to a recognized Collector or contractor.